What Are The Technological Advancements In Concrete Cutting?

Concrete cutting is an essential part of the construction industry but can be very dangerous if the necessary precautions aren’t taken.

However, the latest innovative solutions in concrete cutting not only make it easier and faster than ever before, but they also make it safer. One of these technological advancements is in the actual concrete cutting blades themselves.

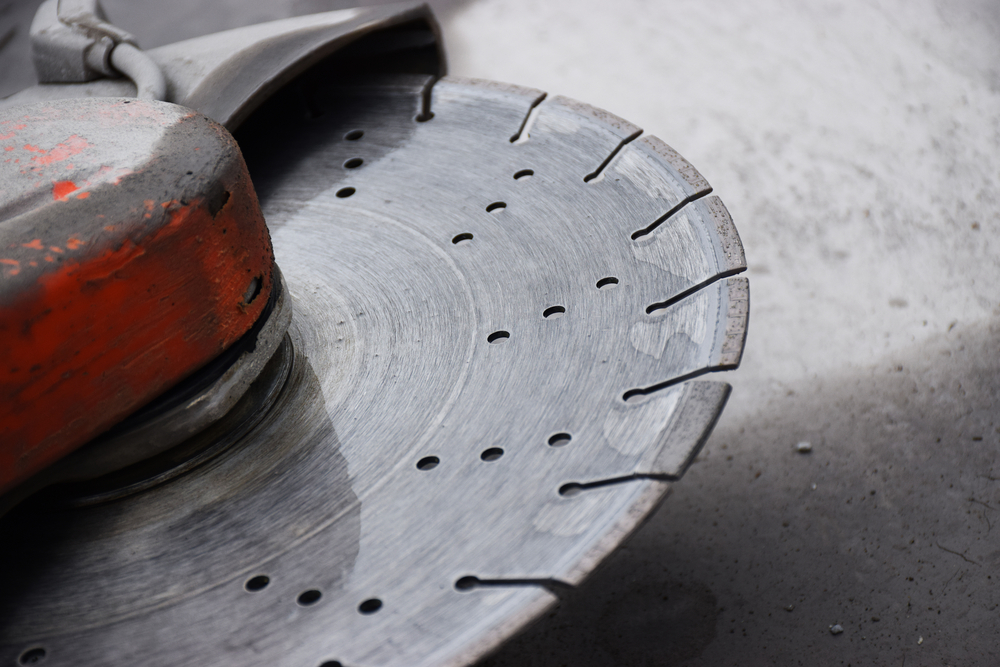

The latest in diamond blade technology allows you to cut through concrete with ease, saving you time and money. No more waiting days or even weeks for your project to get done!

Please continue reading below to learn more about some of the technological advancements in concrete cutting.

What Is Concrete Cutting And How Does It Work?

Firstly, we need to explain what concrete cutting is. Concrete cutting is a process that can be performed in order to level, break up or shape concrete.

This technique involves the use of heavy equipment and powerful water-cooled saws for cutting concrete and other forms of demolition work.

Concrete cutting is typically used when expanding buildings where existing walls need to come down or trenches need to be cut in concrete to remove certain segments.

New Advancements In Concrete Cutting

The concrete cutting industry has evolved significantly in recent years. It is now possible to cut up small sections of a large block, instead of having to excavate the entire thing.

This process can save time and money for both companies that need their project done in a timely manner, as well as those who don’t want heavy equipment onsite during construction or renovation work.

The types of solutions offered have changed with the times. Not only are there new methods like laser technology which allows for precise cuts without any dust at all, but there are also more specialised products available such as highly advanced diamond tipped saw blades.

For example, abrasive teeth with diamond inserts make cutting blades last longer while still being able to cut deep into the material. The advancements in the latest blades can also help to save on time, labour costs and wear-and-tear of tools used in the process.

Three Tips For Saving Money On Your Next Concrete Sawing Project

1). Look for the latest and most technologically advanced diamond blades. This will give you more life out of each purchase because they use diamonds instead of steel teeth. This also cuts down on filing time between jobs since there’s less wear and tear due to their hardness level.

2). Purchase a blade with the right tooth count and pitch to match the type of material you’re cutting through, as well as power rating that will be sufficient enough to cut it effectively in one pass.

3). Use water or other lubricants before starting up so that errant sparks don’t cause a fire, particularly while inside an enclosed area where flames can easily spread if left unchecked! The water or lubricant also helps to keep the blade cool which ensures its longevity.

Always Wear Safety Gear When Using Concrete Saws

Despite the technological advancements in concrete sawing, it is still a very dangerous job. That is why wearing safety equipment (PPE) is vitally important when operating a concrete saw.

Your safety equipment should consist of eye protection to protect your eyes from dust particles and debris flying in the air, heavy duty gloves, a face mask or respirator and ear plugs or ear muffs at a bare minimum.

Then for that extra level of protection, you should also wear a hard hat for head protection against falling objects or debris and boots with steel toes to provide extra foot support. Boots can also provide electrical grounding if you accidentally come into contact with an energised electric conductor on the ground if wet sawing.

Avoiding Accidents While Working With Concrete Cutters

As mentioned previously, despite the latest technology, when it comes to concrete cutting machines, they can still be very dangerous. It is extremely important to know how to use them properly.

If you are using a concrete cutter, make sure your work area is well lit with plenty of room around the site for maneuvering in case things go wrong. Use gloves if possible because once the handles get wet, there will be slippage on the handle which could cause an accident while operating the tool at high speeds.

Also make sure that your work area is clear of other tools and hazards, and is cordoned off so that unauthorised people don’t accidentally find themselves in harm’s way.

As mentioned earlier, it is also also important to have all the necessary PPE. This won’t stop accidents from happening but it will protect you in case something does happen.

Final Thoughts On Concrete Cutting Technology

With the help of technology, concrete cutting is quicker and much safer than ever before. Diamond blade technology in particular is a revolutionary way to cut concrete and other materials.

It not only enhances the cutting process, but it does so in an environmentally friendly fashion. This means there is less noise pollution for our ears; decreased risk of injury due to accidents involving sharp motion from cords and cables and more control over how deep cuts are made.

Diamond blade technology is one of the biggest advantages that concrete cutters have. However, it’s still important to take care when using any type of power tool, especially concrete cutting machines.

We hope that the information in this blog post has been helpful, and we wish you the best of luck with your concrete cutting project.

If you are looking for a concrete cutting company that is trustworthy and reliable, then don’t go past Sydney Sawing & Drilling. Please call us today on (02) 9158 6101 or leave an enquiry.