What Is Bleeding And Segregation In Concrete?

In construction, concrete is among the most commonly used materials. It is made up of fine aggregate, coarse aggregate, water, and cement. Segregation occurs when the ingredients in the concrete separate from each other. This can also affect the quality of the cut when concrete sawing. There are various reasons why segregation occurs. In this article, we will discuss bleeding and segregation, their causes, types, and remedies.

What Is Segregation In Concrete?

Workability is one of the important properties of concrete that determines how easily the concrete mix can be placed. High-quality concrete is uniformly mixed and easy to place without bleeding or segregation.

What Is Segregation?

Segregation occurs in concrete when the ingredients start to separate. Improper mixing is usually the primary reason why the ingredients separate since concrete is classified as a type of non-homogenous material. It usually occurs during the transportation, handling, and placement of the concrete.

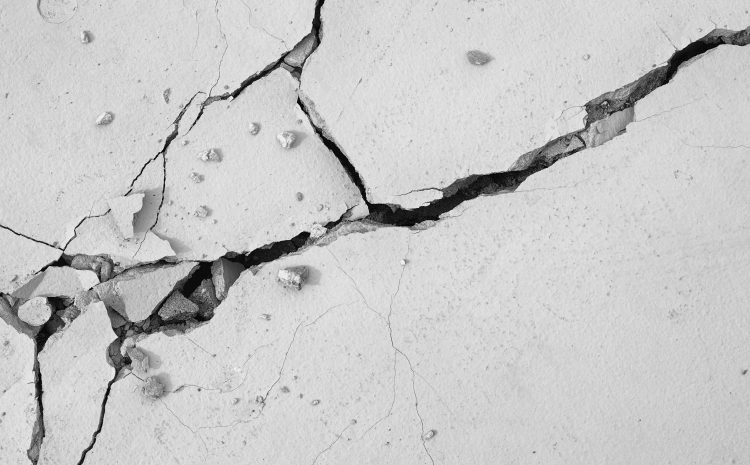

The segregation will also affect the properties of the concrete. The overall strength of the concrete will decrease which can lead to cracking. For this reason, concrete must be mixed properly before it is used in construction.

Common Causes Of Segregation In Concrete

The water-cement ratio, size of the aggregate, and compaction are important factors to consider when preparing a high-quality concrete mix. Below are some of the reasons that cause segregation in concrete:

- The concrete ingredients are not mixed properly

- Poorly grading the aggregates

- Using too much water

- Differences in the size of the aggregates

- Improperly handling the concrete

- Placement of concrete from a greater height

- Overmixing the concrete

Preventing segregation is vital since it adversely affects the concrete’s properties.

Segregation Types

Segregation of concrete involves three types:

1. Separation of cement and water from the other ingredients

2. Separation of the water content

3. Segregation of the coarse aggregates

Segregation is not easy to measure or detect since there are no specific tests to determine it. However, the Flow Table Test is used to measure segregation. The Slump Test can also assist in detecting segregation. The coarse aggregates used in concrete mixes usually settle down for the other ingredients. This typically occurs if the mixture is dry. When the water content separates from the concrete mix, this usually occurs when there is too much water or when there are not enough fine aggregates present in the mixture.

Bleeding

Segregation will occur when the main ingredients used in the concrete such as water, cement, and gravel aggregate separate during or before the curing process. At the same time, segregation will cause water to rise up to the surface. This is a process known as bleeding. Similar to segregation, bleeding is a process that causes the water in the concrete mix to rise to the surface. This causes the concrete to become weak and porous.

Bleeding will affect the durability and strength of the concrete. It will also cause the bond to break between the steel reinforcement and the concrete. Controlled vibration and the correct proportions of ingredients in the concrete will reduce the risk of bleeding. Air-entraining admixtures are also used to reduce bleeding.

What Causes Bleeding In Concrete?

The main reasons why bleeding occurs in a concrete mixture includes the following:

- Segregation is the primary reason why bleeding in concrete occurs.

- The quantity of the fine aggregates and the cement type used.

- High water to cement ratio results in bleeding.

- Over vibration.

How To Lower Bleeding In Concrete

Here are some of the methods used to reduce bleeding in concrete:

- Minimum water to cement ratio needs to be maintained

- Use a mineral admixture such as fly ash

- Use an air-entrapping admixture

- Following the correct design mix

Summary

Segregation and bleeding of concrete can be controlled by correctly proportioning the mixture and only applying the recommended water-cement ratio. Precaution needs to be undertaken during the stages of handling, transporting, placement and compaction. The use of admixtures and air-entraining agents can also help to control segregation.

If you are looking for a concrete cutting company in Sydney that is trustworthy and reliable, then don’t go past Sydney Sawing & Drilling. Please call us today on (02) 9158 6101 or leave an enquiry.